In the early years, agriculture provided an important source of income for Singaporeans. By 1970, about 175,400 people (9% of the total population)1 were actively engaged in agricultural activities, or were indirectly dependent on farming and fishing for a living. Their traditional methods of farming or harvesting were inefficient and laborious. Before AVA was formed, the Primary Production Department (PPD)2 had been providing farmers around the island with extension services, training, and various assistance schemes. Our research and development (R&D) in areas such as production methods, animal nutrition, and disease control also benefitted farmers.

With growing population, urbanisation, and industrialisation, the industry restructured from subsistence to intensive mode of farming. The cultivation of rubber and fruit trees, tobacco, and fodder grass, along with poultry, pig, goat, and cattle farms, gradually made way for the focused production of key food items – vegetable, fish, and egg. In the 1980s and 1990s, Agrotechnology Parks were developed to house modern and productive commercial farms that produce a measure of safe and fresh food.

Into the 21st century, our agricultural landscape is vastly transformed. Innovation, technology, and automation are adopted by farmers to increase yields. With lesser farmland available, more than 90 percent of the food we eat is imported. In the event that overseas food supplies become unstable, it pays to have a level of self-sufficiency to tide us over the shortage. There continues to be a need to strike a balance between demands for limited land and sea space, so farms need to constantly upgrade themselves and raise productivity.

In 2000, AVA assumed PPD’s mandate to ensure food supply resilience, food safety, animal health and welfare, and plant health. We continue to build firm and effective partnerships with farmers to promote local production. This includes conducting R&D on breeding, nutrition, disease control, production systems, and post-harvest technology. These technologies are transferred to farmers, who also receive technical assistance and funding support from AVA. We also encourage them to adopt Good Agricultural Practices that are aligned with internationally recognised standards.

In this special photo story, AVA Vision brings you a glimpse of how technology has helped to transform the farming of eggs, vegetables, and fish in Singapore over 50 years. For a more comprehensive showcase of PPD and AVA's heritage, download a free copy of the e-book Celebrating AVA's Excellence through the Years.

Footnotes

1. In 2014, about 9% of the population was employed in the Community, Social & Personal Services sector, which hired the highest number of residents in Singapore. (Singapore in Figures 2015)

2. PPD, formed in 1959, was restructured into AVA, a statutory board, in 2000.

“The world can learn from Singapore’s success stories. Singapore has made efforts particularly, to maximise productivity from very limited land resources. Commercial indoor and rooftop vegetable farms are opening and other urban and peri-urban agricultural initiatives are taking shape.”

Dr Graziano da Silva,

Director-General, Food and Agriculture

Organisation of the United Nations, 2014

EGG FARMING

In the 1960s and 1970s, Singaporeans either kept chickens in their backyards or in larger commercially viable farms. Farming was done manually.

In 1968, there were thousands of chicken layer farms of various sizes. They produced 315 million eggs that year.

VEGETABLE FARMING

In the 1960s, traditional methods of vegetable gardening were followed, such as the preparation of raised beds, elaborate procedures of sowing, morning-and-evening watering, and frequent hand weeding.

The majority of Singapore’s farmers were engaged in intensive market gardening of fresh vegetables.

Modern vegetable farms today use automation to save time and costs. For example, solar energy is used to automate ventilation fans and supplementary lighting. Irrigation is done via overhead sprinklers.

Automation is employed in the stages of seeding and packaging. Photo shows a mechanised mixer cum compacter requires only 1 instead of 3 workers to loosen peat moss daily.

Vertical farming is a good way to achieve better land-use efficiency. Using a unique water-pulley system, troughs of vegetables are automatically rotated on an aluminium frame to ensure they receive uniform sunlight, irrigation, and nutrients.

Companies are also exploring vertical farming to grow leafy vegetables indoors. In a controlled environment, vegetables can be grown indoors under LED and fluorescent lighting. AVA is also developing an automatic indoor multi-tier seedling production system that has the potential to increase productivity by 4 times and reduce water usage by 90%.

FISH FARMING

In the 1960s, the main inshore fishing methods were kelongs and other fixed traps, various types of lines, beach seines, drift nets and push nets.

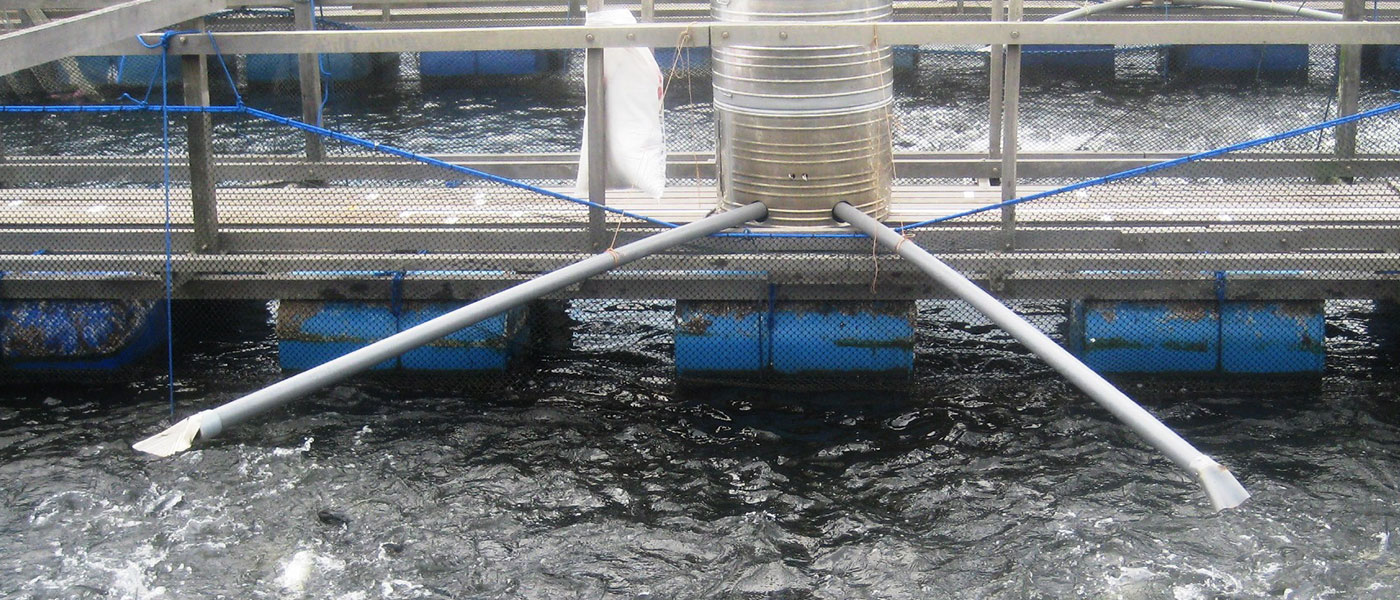

In the 1970s, PPD began to encourage kelong operators to venture into cage-net cultivation of fishes. Photo shows a floating cage-net structure with movable pontoon attachment for culture of groupers and other marine fish.

Today, movable pontoon attachments are replaced with upgraded versions such as the modular floating high-density polyethylene cube cage. These cages are easier to assemble and maintain, thus reducing manpower needs.

Aquaculture in the 21st century embraces automation and technology to reduce the reliance on manpower. Through the Recirculating Aquaculture System, water can be re-used for fish culturing through multi-level water treatment processes. It also protects fishes against adverse environmental conditions when farmed indoors.

Today’s coastal fish farmers raise productivity of high quality fish with the use of automatic fish feeders, graders, as well as water monitoring and aeration equipment. Photo shows a farm equipped with automatic fish feeders.